| |

|

| Pneumatic Connection Solutions: Pneumatic Fittings, Pneumatic Push in Fittings and Pneumatic Connectors. |

| News From NingBo Pace Pneumatics Co.,Ltd. |

|

| Choosing Durable "No-Air-Leak" Pneumatic Tubing Fittings |

Over many years of reviewing industrial compressed air production machinery, of many types and styles, there is one common thread or complaint; “push-to-connect pneumatic tubing connections or push-to-connect pneumatic tubing fittings are a continual source of compressed air leaks and production interruptions.” Probably seventy-five to eighty percent of push-to-connect type tubing fittings use flexible tubing selected for lower material cost and assembly rather than an alternate appropriate hard metallic tubing.

Flexible tubing itself is much more prone to leaks from vibration, abrasion, chemical abuse, etc. than correctly selected and installed hard metallic tubing. The flexibility and constant transmission of vibrations and movement to the sealing area of the push-to-connect fitting tends to shorten its’effective life. The objective of this article is to contrast the operating benefits, under demanding operating conditions, of the typical push-to-connect fittings and the alternative two-piece ferrule sealing wedge fitting.

Typical Two-Piece Ferrule Mechanical Grip

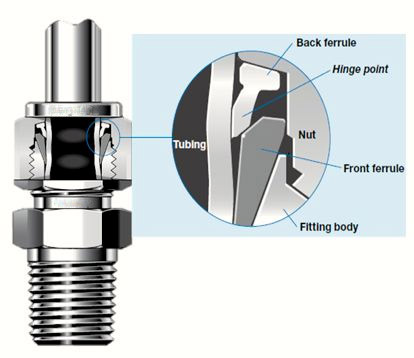

Wedge Fitting |

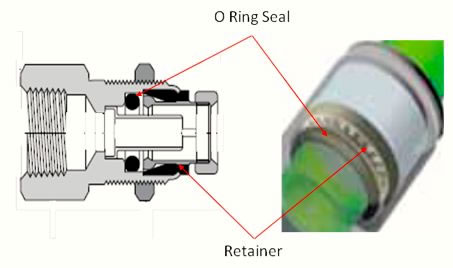

Typical Push-to-Connect Fitting |

|

|

Fitting Fundamentals

When subjected to vibration, typical push-to-connect fittings can exhibit relative movement by the tube on the O-ring and retainer (also called grippers). This will accelerate wear issues leading to a higher propensity to leak. At some point, the fittings useful life is gone when both the retainer and seal areas are too worn. Some designs use ribbed seal material instead of O-rings.

The two-piece ferrule sealing wedge fitting design holds the tubing in place with the back-ferrule. The wedge seal on the tubing, is formed by the front ferrule, pushed by the back ferrule, as the fitting is tightened. There is very little (if any) relative movement between the fitting and tubing - so wear is minimal. This design exhibits reliable durability as any wear that may occur can easily be offset with a small amount of tightening.

Typical Push-to-Connect Fitting

Typical Two-Piece Ferrule Wedge Type Fitting

Examining Pneumatic Fittings and Tubing on Production Machinery

It would be to any plants advantage to monitor the inlet compressed air flow and pressure to any production machinery using a significant number of tubing and fittings. If possible, set a “Best Practice” standard for compressed air use when new (or completely repaired). Then monitor compressed air flow and pressure for deviations from the “Best Practice Flow and Pressure”. Any deviation will provide a good indication of compressed air leaks – which can and should be repaired

In order to arrive at the above “Best Practice” scenario, the type and size of the operating tubing should also be reviewed. We have found cases where productivity was down or the pressure had increased because ¼” copper tubing had been replaced with ¼” nylon tubing and was not capable of delivering the same compressed air flow at the necessary pressure.

The cross-sectional area of standard 100 psig rated copper tubing is about 30 times larger than standard ¼” polyethylene high flow tubing. Often you will have to up-size the nylon or poly-type tubing to replace ¼” copper or other hard metal tubing. This data will vary by manufacturers and sources.

A Case Study

On a recent plant compressed air system review, Air Power USA was requested to do an in depth analysis of seven operating packaging lines. This plant felt the compressed air leak-load, on the packaging machines, continued to remain above acceptable levels.

These seven packaging lines had been operating for just over five years. Plant management indicated that identified leak repairs were almost constant on all seven production lines. They compressed air leaks kept appearing and it was impossible to have a “no air-leak” situation! The plant asked us to identify the magnitude of the compressed air leaks and what actions would be appropriate to permanently eliminate (or at least greatly reduce) the negative impacts: production down-time, scrap, and lost compressed air.

To begin, we held discussions with the plant personnel and discovered some interesting facts:

- Almost all leaks occurred at the fitting seal. Corrective action was to either just push it in again or cut the tubing end off and then reinsert it into the push-to-connect fitting.

- Maintenance personnel liked this aspect of the push-to-connect fitting style because it was quick and easy.

- Maintenance personnel confirmed that probably only half of their repairs were reported and logged. If this was accurate, then the management estimate of compressed air leaks was seriously understated.

- Only when a fitting could not be reset was replacement considered and then the production unit had to be shut-down longer for this to be implemented.

- There were no records kept of continued leaks at specific fittings.

- There had never been a planned project to replace all of the fitting at one time.

We then examined the seven production lines and focused on the seven inserter and seven case packing machines on each line. An inventory was made of the tubing and fittings on the pneumatic circuits of each machine.

Reviewing Fittings on the Seven Inserter and Case Packer Machines

The seven (7) inserter machines each deployed ten (10) double-acting pneumatic cylinders. Each machine had eight smaller pneumatic cylinders fed with 1/4” standard push-to-connect fittings and 1/4” nylon tubing. They then also had two larger pneumatic cylinders fed with 3/8” similar push-to-connect fittings and tubing. All fittings were supplied by the OEM machine manufacturer. The total fitting count on the inserter machines was:

- 26 x push-to-connect fittings: 1/4” x 1/4” size

- 4 x push-to-connect fittings: 3/8” x 3/8” size

The seven (7) case packer machines each deployed fifty-one (51) double-acting pneumatic cylinders. Each machine had fifty smaller pneumatic cylinders fed with 1/4” standard push-to-connect fittings with polyurethane or nylon 1/4” tubing. They then also had one larger pneumatic cylinder fed with similar 3/8” push-to-connect fittings and tubing. All fittings were supplied by the OEM machine manufacturer. The total fitting count on the case packer machines was:

- 75 x push-to-connect fittings: 1/4” x 1/4” size

- 4 x push-to-connect fittings: 3/8” x 3/8” size

Solutions

Compressed air inlet pressure and flow data (to the inserter and case packer machines) was collected on each line running during normal production hours. This data was averaged and recorded. Complete leak repairs were made on all fourteen (14) machines and were tested with both ultrasound leak detectors.

In order to eliminate leaks, caused by the fittings, we replaced the standard push-to-connect fittings with the two-piece ferrule wedge design. The project cost, for materials, was $2,270.00. As a reference, we calculated the cost to be $2,151.00 if we had used the less durable push-to-connect fittings.

When a production unit was deemed to have zero compressed air leaks it was run again and a “Best Practice” pressure and air flow was measured and recorded with the same flow meter and gauge. The total electrical energy savings for the seven production lines, associated with the reduction in compressed air leaks, was estimated at $44,637 per year. This was calculated assuming a cost for compressed air of $122.63 per scfm per year. It also assumed that only fifty percent (50%) of this value would actually be recovered.

Savings Calculation: 104 scfm x $122.63 scfm/year x .50 (%) x 7 lines = $44,637 per year

Fitting Type Cost Comparison

Average Compressed Air Flow Savings Per Production Line

Conclusion

At this plant, the seven production lines of inserter and case packer machinery required the introduction of wedge-type fittings to eliminate compressed air leaks. The tubing was not the primary cause of the leaks. Sometimes this is not true partially in areas with “wash down” cycles.

When movement in the line is required, flexible tube or hose will be appropriate. Proper selection of the material is critical. If no movement in the line is required during operation, then wedge-type fittings with properly selected hard metal tubing will further minimize or eliminate operating leaks.

Finally, if production equipment is using standard push-to-connect fittings and there are no compressed air leaks - there is no reason to change. We strongly suggest, however, keeping careful records of compressed air repairs, flow and pressure to maintain operational efficiency. |

|

|

|

|

|

Pneumatic Fittings, One touch tube fittings, Push in fittings, Air fittings, push to connect fittings, Push To Connect Tube fittings, All metal push in fittings, brass air fittings, Steckverschraubungen, Pneumatik-Zubehör, Pneumatyka, Drosselrückschlagventile, alle Gewindefittinge mit geradem G-Gewinde, NPT-Gewinde, NEUMÁTICA RACORES, Pneumatique raccord, Raccorderia. Plastic Pneumatic Fittings, Pneumatic Accessories, Pneumatic Push in Fittings, One Touch Fittings, Nickel Plated Brass Push in Fittings, Air Flow Control valves, Pneumatic flow control valves, Hand Valves, Air Silencers, Air Muffler, Nylon Tubing, Air Tubing, Quick Couplers, Air Line Fittings, Airline Fittings, Quick coupling, Push to Connect Tube Fittings, Pneumaitc Instant fittings, Metal Push in Fittings, Brass Air Fittings, Metal Instant Fittings, Brass Instant Fittings, Metal One Touch Fittings, Brass One Touch Fittings, Compact One Touch Fittings, Push in air fittings, Push in Instant Fittings, Tube Fittings, Air Quick Fit Fittings, Speed Controllers, Air Flow Control Valves, Hand Valves, Air Blow Guns, Mini Push in Fittings, Brass Fittings, Miniature Pneumatic push to connect fittings, Metric Push in Fittings, Compact One Touch Fittings, Flow Controller, Pneumatic Couplings, all brass air Fittings, Heavy Duty Air Duster Gun, Hand Throttle Valves, Inch Composit Push in Fittings, Inch Instant Fittings, Metric Instant Fittings, Two touch Fittings, pneumatic push on Fittings, Push To Connect schrader valves, Pneumatic Check valves, Stop fittings, Compression Fittings, Push lock misting Fittings, Push Fit Fittings, D.O.T. push to connect air brake fittings, DOT push in fittings, Brass D.O.T. air fittings, DOT air brake compression fittings, Threaded Fittings, BSP Fittings, DOT Air Hose Fittings, Brass Hose barb fittings, air connectors, air pipe fittings, Pneumatic Connectors, DOT Tubing, DOT Air Brake Tubing, SAE J844 air brake tubing, brass DOT air brake fittings, pneumatic component, Air Suspension |

|

|

|

|